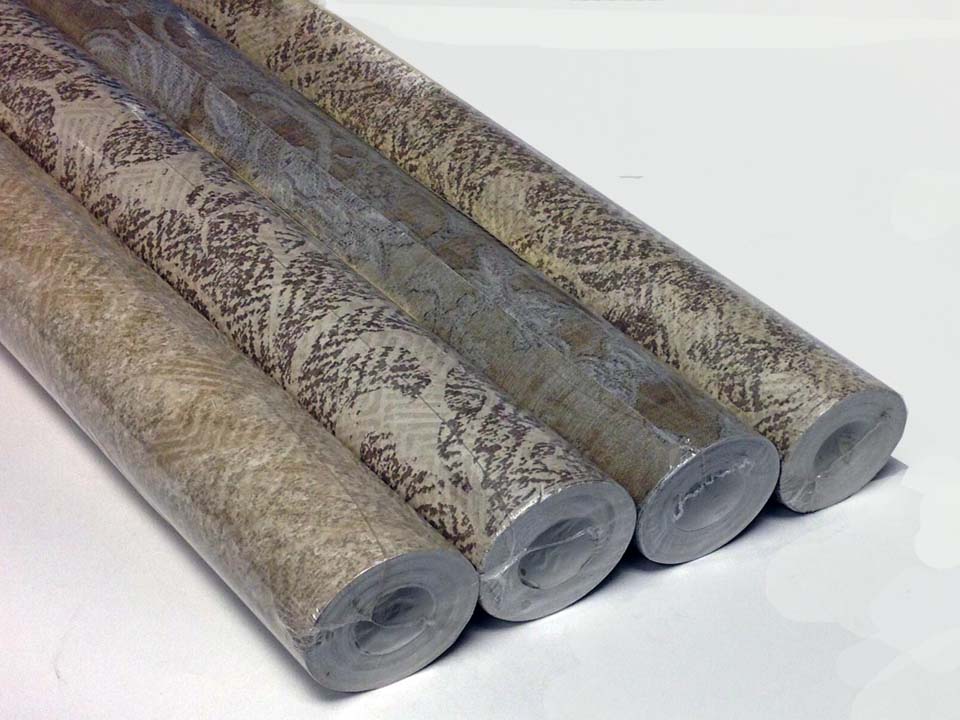

Img source : texwrap.com

Read on here to know the uses and importance of shrink wrap.

Shrink wrap or shrink film is made up of polymer plastic film. It is wrapped around the objects of all shapes and sizes. Heat is applied to its surface to cause it to shrink so that it adapts to the shape of the object and seal itself.

The Wrapping Process:

Shrink wrap is a straightforward process as it needs two things—a plastic wrap and heat. There are many types of shrink wrap. Smaller items are kept in a shrink wrap bag and then heated with a heat gun. Shrink wrap machine is also used to wrap, heat and seal the larger products.

Shrink wraps protect the product from water, weather, and tampering.

Types of Shrink Wrap:

Shrink wrap is available in many forms. Flat roll-stock is used to wrap around a product, often with heat sealing to clip the film together. Centerfold film is supplied on a roll with the pre-folded plastic in half, the product is kept in the center part, and the edges are then sealed to form an enclosure. Then, heating is applied to make the bag to shrink around the product. Pre-formed plastic shrink bags come with one end open, the product is kept in the bag, sealed and treated with heat shrinking.

Where Shrink Wrap is Used?

Shrink wrap is used to wrap up books, CDs, or DVDs boxes and software licenses. They are commonly used as an overwrap for cartons, boxes and beverage cans.

Shrink wrap is also used as the covering of foods like meats, cheese, veggies and plants to keep them clean and tamperproof.

Benefits of Shrink Wrap

Protection:

Shrink wrap creates a tight seal when they are treated with heat. This tight seal protects the wrapped content from weather, water, and tampering. Once sealed, the covered items are less prone to the risk caused by dirt, moisture or dust. Some shrink wrap also offers UV protection to protect the products of the sun’s harmful rays. They are used to wrap up small electrical wires to avoid them getting exposed to moisture.

Food-grade shrink wrap is used for some food products that are needed to be preserved for transport or extend shelf life.

Durability:

Durable and sturdy plastic is used to create shrink wrap. They are not easy to puncture or tear. They maintain their durability even in the sun or extreme frozen conditions.

Tamperproof:

Since shrink wrap seals and conform around the product once they are heated, any tampering will be highly noticeable. That’s why many CDs, DVDs, books and software licenses come in this packaging type. Pharmaceutical and food manufacturers also use shrink wrap for their products. Some certain types of shrink warps used by federal agencies or financial institutions tend to change color when the plastic has tampered, to indicate that the seal has been handled roughly.

Affordability:

Shrink wrap won’t dent your budget as they are generally affordable than most packaging options. It occupies less space and keeps items close together without big materials like boxes. This way, it helps you save space and money, both in shipping and storage.

Marketing:

Shrink wrap can be designed with words, pictures, colors, and logos just like your primary packaging.

Flexibility:

From small electrical wires to big hardware, shrink wrap can cover the things of any shape, any size. For example, shrink wrap kits are available to weatherize boats and greenhouses. They are used for freight on trailers and trains for easier transport. Sometimes entire buildings can be wrapped to protect them from chemical leaks and hazardous materials.

So you must have understood the uses and benefits of shrink wraps. What do you think? Please let us know by commenting below.

Over the past some years, technology has become an integral part of the classrooms across the USA. It is common to see students using tablets, laptops and other devices to read, write and learn. In this ever increasing technology intrusion, it is obvious to think that paper will be out of the scene, sooner or later. However, it seems impossible as students are still choosing to do their important learning on paper. According to a recent study, paper is still important to productive learning.

Over the past some years, technology has become an integral part of the classrooms across the USA. It is common to see students using tablets, laptops and other devices to read, write and learn. In this ever increasing technology intrusion, it is obvious to think that paper will be out of the scene, sooner or later. However, it seems impossible as students are still choosing to do their important learning on paper. According to a recent study, paper is still important to productive learning.