Product integrity builds customer trust. And it leads to long-term customer loyalty and sustainable business growth as well.

Whether it is a pharmaceutical business, food brand, or a financial organization, companies are looking for reliable security packaging solutions to prevent unauthorized access and clearly show when tampering has occurred. That’s why tamper-evident packaging is an important investment.

Let’s explore the top 10 tamper-evident packaging solutions that offer maximum security and peace of mind.

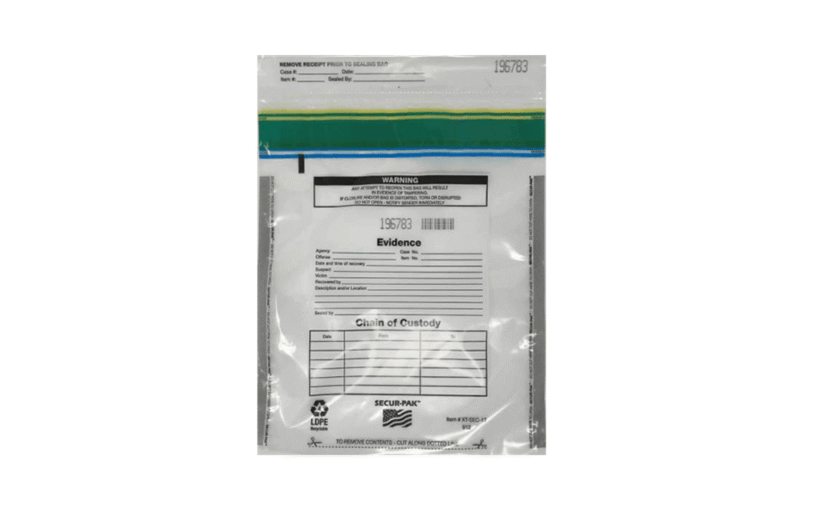

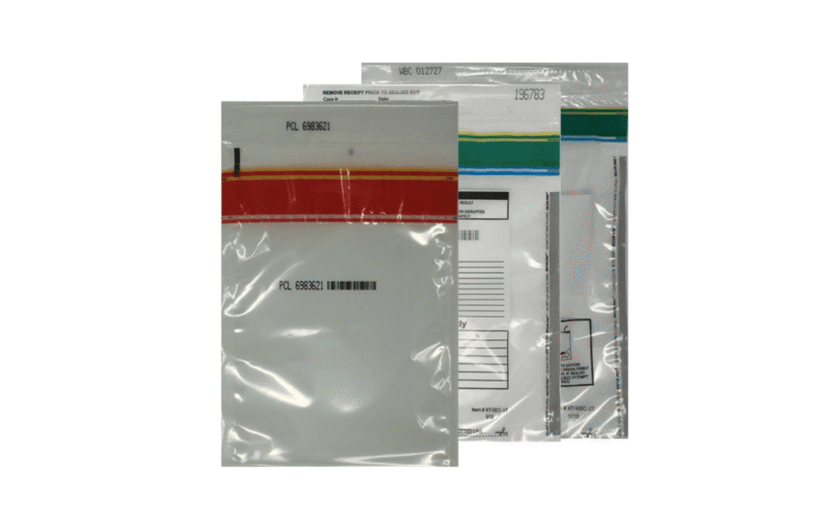

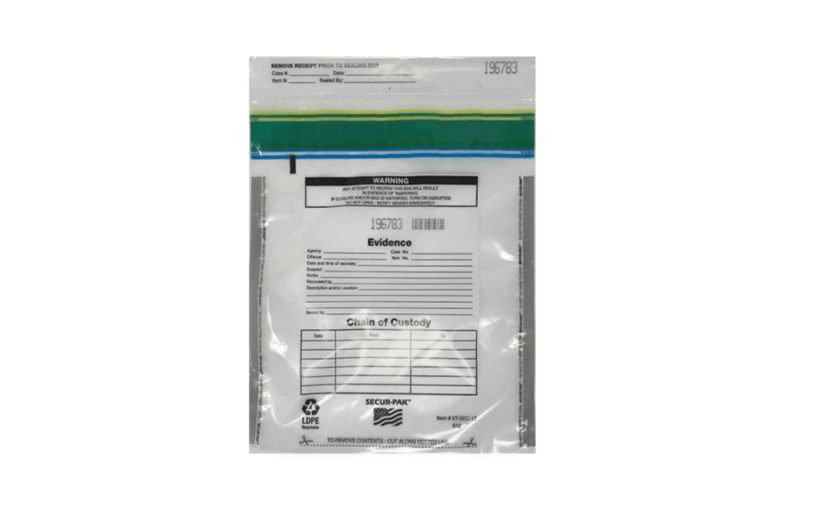

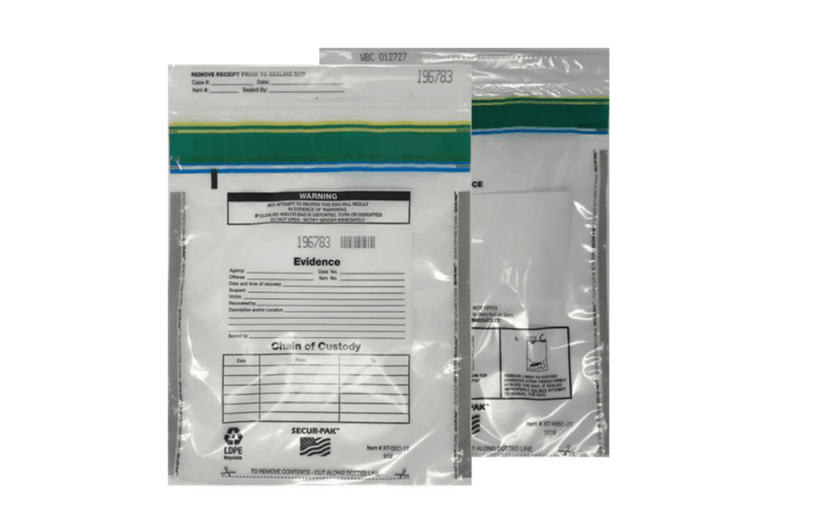

Tamper-Evident Bags

Tamper-evident bags are one of the most popular types of anti-tamper packaging, and they are used in carrying cash, confidential documents, lab samples, and pharmaceuticals.

These bags have permanent adhesive closures or heat-sealed closures. These closures cannot be resealed once they are opened. Advanced-level tamper-evident bags come with color-changing indicators that show whether the seal has been tampered with.

Ideal for: Banking, law enforcement, medical testing, and retail deposits.

How it works: Once these bags are opened, visual proofs of tampering are evident.

Security Tape and Labels

Security labels and security tapes are simple yet effective security packaging. When someone tries to tamper with them, they leave a mark of visible VOID or a destructible residue, which shows that the package has been opened or tampered with.

They can be personalized with logos, serial numbers, or barcodes for additional authenticity.

Ideal for: E-commerce packages, electronics, and high-value retail items.

How it works: The adhesive and design of the label do not allow one to remove or replace it without leaving evidence of manipulation.

Tamper-Evident Seals

Tamper-evident seals are commonly used across all industries. They offer excellent protection to containers, bottles, and drums. Such seals are normally composed of plastic, metal, or cable ties and have to be torn to access the container.

They may be labeled or coded to improve tracking and avoid illegal replacement.

Ideal for: Chemical drums, food containers, and logistics.

How it works: A broken or missing seal is an immediate red flag that the package was opened.

Shrink Bands and Wraps

Shrink bands are mostly used for products like beverages, cosmetics, and drugs. These are thin plastic bands used to fit tightly around the caps or lids and contract when heated. Any effort to take off the cap breaks the band, which is an indication of tampering.

Ideal for: Bottled drinks, health supplements, and personal care products.

How it works: The slim fit makes any interference easily noticeable, and the bands can be branded to make them even more attractive.

Blister Packs

Blister packs are commonly used in the pharmaceutical and consumer goods business, where each item is sealed in a plastic cavity. The packaging cannot be resealed once it is opened without showing any signs of damage.

Ideal for: Tablets, capsules, batteries, and small electronics.

How it works: The product is sealed in an individual pack that will avoid contamination and will be authentic.

Induction Seals

Induction seals, which are foil liners, are heat-sealed to the rim of the container and are used primarily on bottles and jars. The seal has to be removed when the customer opens the cap, and this provides a clear indication that the product has not been tampered with.

Ideal for: Food and drinks, health supplements, and cosmetics.

How it works: The seal not only prevents tampering but also ensures that the product is fresh and leak-proof.

Tamper-Evident Caps and Closures

A lot of bottles and jars come with anti-tamper packaging designs that have built-in security measures. An example is the plastic caps, which have a breakaway ring or foil-sealed tops, which indicate when a product has been opened.

Ideal for: Edible oils, medicines, and beverages.

How it works: The physical break or tear on the cap ring would give immediate evidence of tampering.

Zip Closure Tamper-Evident Pouches

In the case of flexible packaging, tamper-evident pouches are used to combine security and resealability. Such pouches usually have a strip to tear away above the zipper. The strip has to be torn by the consumer, and the pouch can be resealed.

Ideal for: Coffee, snacks, pet food, and nutraceuticals.

Why it is effective: The tear strip makes it impossible to access it more than once, and the zipper is convenient once opened.

Electronic Tamper-Evident Packaging

Electronic tamper indicators are gaining popularity with the development of smart packaging. These solutions employ RFID tags or sensors that notify manufacturers or consumers in case a product has been opened, dropped, or subjected to abnormal conditions.

Ideal for: High-value products, pharmaceuticals, and defense products.

How it works: It is nearly impossible to interfere with real-time monitoring and data tracking.

Holographic Seals and Films

Holographic seals are not only attractive to the eye, but they are also almost impossible to replicate. These films have both tamper-evident seals and anti-counterfeit protection. The holographic pattern is destroyed when one attempts to peel or cut it, which proves that the product was tampered with.

Ideal for: Luxury products, electronics, and branded products.

How it works: It has both visible tamper evidence and authenticity verification in a single package.

The importance of Tamper-Evident Packaging.

Tamper-evident packaging is not only a matter of security, but also reputation. When a customer purchases a product, they trust that it is safe, authentic, and untouched. That trust can be ruined by one tampered object.

The benefits of good anti-tamper packaging to your business are as follows:

- Guarantees brand integrity: Tamper protection is a feature associated with professionalism and reliability.

- Avoids contamination of products: This is essential, especially in food and pharmaceuticals.

- Deters embezzlement and forgery: Obvious security measures deter manipulation.

- Complies with regulations: In most industries, tamper-evident seals are mandated by law.

When combined with traceability tools like barcodes or RFID tags, tamper-evident systems create a complete security packaging solution that protects products through every stage of the supply chain.

The Bottom Line:

So you must have understood why and how tamper-evident solutions work to protect your products, thereby ensuring trust and compliance. While there are many tamper-evident packaging to choose from, make sure to prefer the one that can meet your needs better. For example, induction seals are suitable for liquids, while zip pouches or blister packs can be used for dry goods.

You can reach out to packaging experts like iSell Packaging to find the right packaging for your industry. We offer tailored packaging solutions backed by experience, expertise, genuine pricing, and timely delivery. Let us know how we can fulfil your packaging needs.