Flooding is a major concern for many communities around the world, and effective flood defense is crucial.

For centuries, traditional sandbags have been the go-to solution for holding back floodwaters. However, an innovation has emerged in the form of sand less sandbags, which promise to revolutionize flood defense.

In this blog, we’ll explore what makes sandless sandbags better than traditional sandbags, highlighting their advantages and how they compare to their traditional counterparts.

Understanding Sandless Sandbags

Sandless sandbags, also known as water-activated flood bags, are an innovative flood defense tool designed to absorb water and expand, creating a barrier against floodwaters.

Unlike traditional sandbags, which are heavy due to the sand inside, sandless sandbags are lightweight and easy to handle when dry. The secret lies in the super-absorbent material inside the bags, which swells upon contact with water, mimicking the effectiveness of sand-filled bags without the need for sand.

Quick and Easy Deployment

One of the most significant advantages of sand-less sandbags is their ease of deployment. Traditional sandbags require substantial effort to fill with sand, transport, and stack. This process is labor-intensive and time-consuming, often requiring a coordinated effort from multiple people. In contrast, sandless sandbags are light and easy to store when dry, making them ready for rapid deployment when a flood threat arises.

When water comes into contact with a sandless sandbag, the super-absorbent polymer inside begins to swell, and within minutes, the bag is fully inflated and ready to use. This quick response time is crucial in emergencies where every second counts.

Efficiency in Storage and Transportation

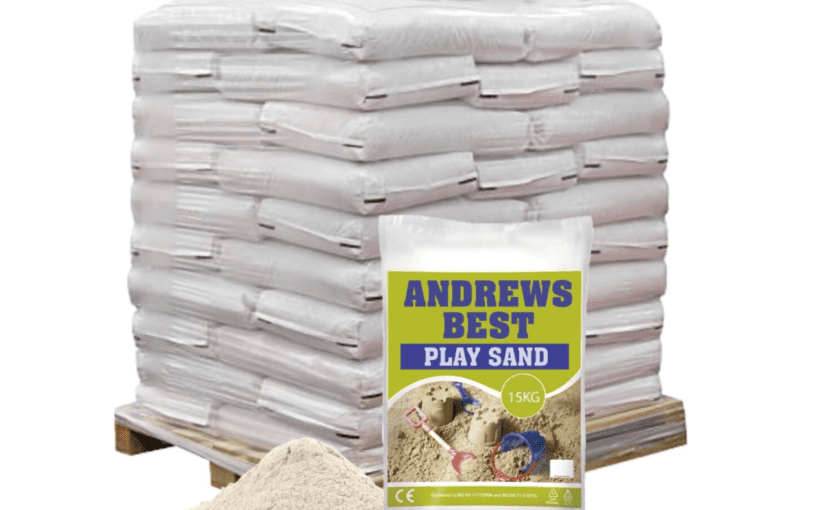

Storing and transporting traditional sandbags can be a logistical nightmare. The bags are heavy, bulky, and require significant space. For instance, a single pallet can hold only 60 traditional sandbags.

On the other hand, sandless sandbags are compact when dry, with a single pallet able to accommodate up to 720 such bags. This dramatic difference in storage efficiency makes sand-less sandbags a more practical solution for both homeowners and large organizations.

Durability and Longevity

Traditional sandbags have several drawbacks in terms of durability. When they get wet, the fabric often breaks down, leading to leaks and spills. Over time, the sand inside can turn into mud, further compromising the integrity of the barrier.

In contrast, sand-less sandbags are designed to withstand wear and tear. The super-absorbent polymer inside is encased in a durable plastic material that does not break down when wet. This means that sandless sandbags maintain their protective properties even after extended exposure to water, making them a reliable choice for flood defense.

Versatility and Adaptability

Sandless sandbags are designed to adapt to various environments and conditions. They retain an even shape when they expand, making them easy to stack and creating a more stable and impermeable barrier. Traditional sandbags, on the other hand, can slump and form irregular shapes, which can lead to unstable and leaky barriers. The uniform stacking pattern of sandless sandbags ensures a more effective defense against floodwaters.

Reusability vs. Disposable Nature

One of the significant advantages of sand-less sandbags is their reusability. Once the flood threat has passed, sand-less sandbags can be dried out and stored for future use.

This is a stark contrast to traditional sandbags, which are often considered disposable after a single use due to the contamination of the sand and the degradation of the bag material.

The reusable nature of sandless sandbags not only makes them more cost-effective in the long run but also environmentally friendly.

Accessibility and Ease of Use

Another critical factor that sets sand-less sandbags apart is their accessibility. Because they are lightweight and easy to handle, they can be deployed by anyone, regardless of physical ability. This is particularly beneficial for vulnerable populations, such as the elderly or individuals with disabilities, who may not be able to manage the heavy lifting required with traditional sandbags.

Institutions like hospitals and nursing homes, as well as individuals living in flood-prone areas, can significantly benefit from the ease of use of sandless sandbags.

Environmental Impact

In terms of environmental impact, sandless sandbags have a clear advantage over traditional sandbags. The reusability factor reduces waste, and since they do not involve the use of sand, there is no risk of introducing foreign materials into the local ecosystem. Traditional sandbags, after use, often end up in landfills or contribute to soil erosion if the sand is not properly disposed of. By choosing sandless sandbags, individuals and organizations can make a more environmentally conscious decision.

Cost Comparison

While the initial cost of sandless sandbags may be higher than traditional sandbags, their long-term cost-effectiveness becomes apparent when considering factors like reusability, reduced labor costs, and easier storage and transportation.

The savings in labor alone can be substantial, as sandless sandbags eliminate the need for shoveling and filling, allowing for quicker and more efficient deployment.

Pros and Cons: Sandbags vs. Traditional Sandbags

Pros of Sandless Sandbags:

- Lightweight and easy to handle when dry

- Quick and easy deployment

- Compact storage and efficient transportation

- Durable and resistant to wear and tear

- Reusable and environmentally friendly

- Accessible for individuals of all physical abilities

Cons of Sandless Sandbags:

Higher initial cost compared to traditional sandbags

Requires water to activate (not suitable for arid conditions without water access)

Pros of Traditional Sandbags:

- Familiar and widely used

- Effective when properly deployed

Cons of Traditional Sandbags:

- Heavy and labor-intensive to fill and transport

- Bulky and difficult to store

- Prone to leaks and degradation over time

- Often disposable and environmentally unfriendly

Conclusion

In the battle of sandbags vs. traditional sandbags, sandless sandbags emerge as the superior choice for modern flood defense.

Their ease of use, efficiency in storage and transportation, durability, and environmental benefits make them a practical and cost-effective solution. As communities continue to face the challenges of flooding, the adoption of sand-less sandbags can provide a more reliable and accessible means of protection.

Whether for individual homeowners or large organizations, sand less sandbags represent a significant advancement in the quest to safeguard lives and property from the devastating effects of floods.