In today’s competitive marketplace, packaging is no longer just about protecting a product, it plays a critical role in branding, customer experience, and sales growth. For small brands trying to stand out on crowded shelves or online marketplaces, flat pouch packaging has become a popular and practical solution. Understanding the right features can help businesses choose packaging that not only looks appealing but also supports long-term success.

This blog explores the most important flat pouch packaging features every small brand should know, how customization adds value, and why flat pouches are often considered the best packaging for small businesses.

Why Flat Pouch Packaging Is Ideal for Small Brands

Flat pouches are lightweight, flexible packaging solutions that offer a balance of functionality, aesthetics, and affordability. Unlike bulky boxes or rigid containers, flat pouches take up less space, reduce shipping costs, and provide excellent shelf presence.

For growing brands, custom flat pouch packaging allows flexibility in design and quantity, making it easier to test new products or enter new markets without high upfront costs. Flat pouches are commonly used for food items, supplements, cosmetics, pet products, and even non-food goods, proving their versatility across industries. Explains how sachet pouches offer convenient, cost-effective, customizable, sustainable single-use packaging ideal for samples, supplements, cosmetics, and premium products.

Customization: A Must-Have Feature

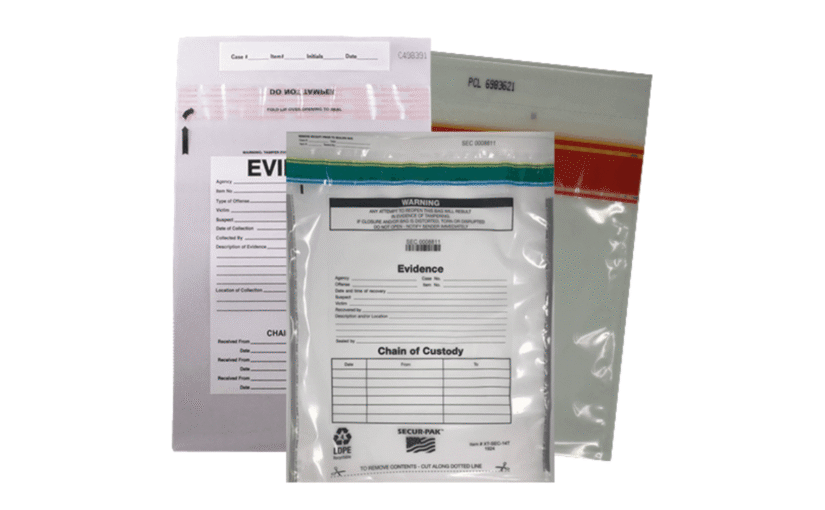

Customization is one of the most important factors when selecting packaging. Custom flat pouches for small brands allow businesses to reflect their brand identity through colors, logos, typography, and messaging. This visual consistency builds brand recognition and trust among consumers.

Custom sizes and shapes also help brands match packaging to product volume, minimizing waste and improving presentation. With custom options, small businesses can compete visually with larger brands without compromising on quality or design. Highlights versatile applications of flat poly bags in food storage, retail packaging, shipping, organization, agriculture, medical, and promotional uses

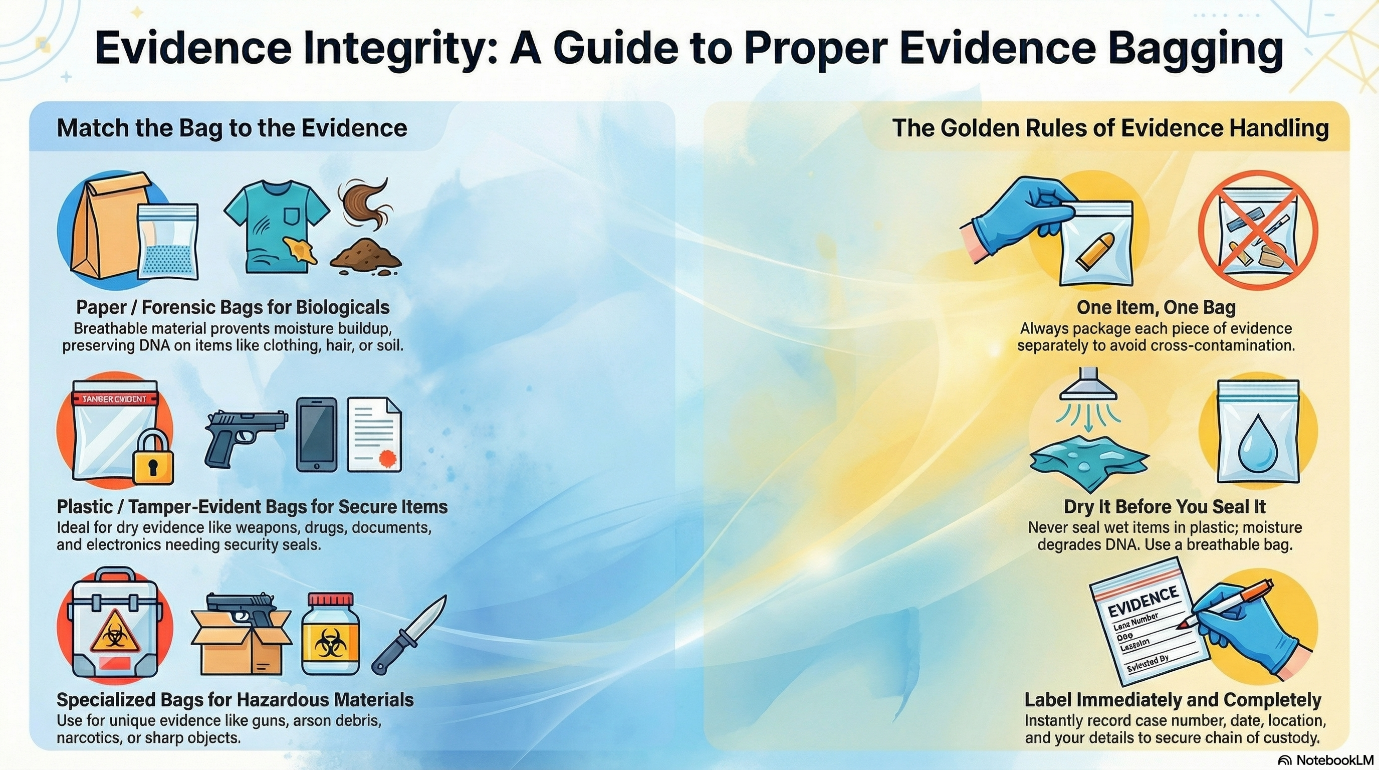

Barrier Protection for Product Safety

One of the most valuable flat pouch packaging features is barrier protection. Flat pouches can be designed with multiple layers to protect products from moisture, oxygen, light, and contaminants. This is especially important for food, supplements, and sensitive products where freshness and shelf life matter.

Strong barrier properties ensure that products remain safe and effective from production to consumption, helping small brands maintain quality standards and customer satisfaction.

Resealable Closures for Convenience

Consumers today value convenience, and resealable closures are a key feature that enhances usability. Zippers, press-to-close seals, and tear notches make flat pouches easy to open and reseal, keeping products fresh after first use.

This convenience is one of the major custom pouch packaging benefits, as it encourages repeat usage and improves the overall customer experience. Products that are easy to store and reuse are more likely to be repurchased.

Cost-Effectiveness for Growing Businesses

Budget considerations are crucial for small brands. Flat pouch packaging is often more affordable than rigid alternatives due to lower material usage and reduced transportation costs. This affordability makes flat pouches the best packaging for small businesses looking to balance quality with cost efficiency.

With custom flat pouch packaging, brands can order smaller quantities without sacrificing professional appearance, making it easier to scale operations as demand grows.

Shelf Appeal and Brand Visibility

Flat pouches offer a large printable surface area, allowing brands to showcase their messaging clearly. High-quality printing techniques such as matte, gloss, or metallic finishes help products stand out in retail environments.

For small brands, strong shelf appeal is critical. Eye-catching flat pouches can capture attention quickly, communicate value, and influence purchasing decisions, especially in competitive categories.

Sustainability Options

Modern consumers are increasingly eco-conscious, and packaging choices can impact buying behavior. Many flat pouches are now available in recyclable, compostable, or reduced-plastic materials.

Choosing sustainable options enhances brand reputation and aligns with consumer values. These environmentally friendly choices add to the overall custom pouch packaging benefits, helping small brands appeal to a wider, more conscious audience.

Lightweight and Easy Storage

Flat pouches are lightweight and easy to store, which benefits both businesses and consumers. For brands, this means lower warehousing and shipping costs. For customers, flat pouches are easy to carry, store, and dispose of.

This practicality is one reason custom flat pouches for small brands are gaining popularity across various product categories.

Versatility Across Product Types

Another advantage of flat pouch packaging is its adaptability. Flat pouches can be used for powders, liquids, solids, and granules. From coffee and snacks to skincare products and household items, flat pouches accommodate a wide range of needs.

This versatility reinforces why flat pouches are considered the best packaging for small businesses aiming to expand product lines without changing packaging formats frequently.

Supporting Brand Growth and Scalability

As small brands grow, packaging must adapt to increasing demand and market expansion. Flat pouch packaging offers scalability without major changes in production processes. Brands can start with simple designs and gradually upgrade materials, finishes, or sizes as they expand.

This scalability highlights the long-term custom pouch packaging benefits for startups and emerging businesses focused on sustainable growth.

Conclusion

Choosing the right packaging is a strategic decision for any small brand. Understanding essential flat pouch packaging features, such as customization, barrier protection, resealability, affordability, and sustainability, can help brands make informed choices that support both branding and functionality.

With custom flat pouch packaging, small businesses gain the flexibility, professionalism, and efficiency needed to compete in today’s market. Whether launching a new product or refining an existing one, flat pouches remain one of the most practical and effective packaging solutions available. iSell Packaging offers high-quality custom and plain retail, grocery, tote, and specialty bags, manufactured in the USA for versatile packaging needs. Reach out to us for custom retail, paper, plastic, and specialty packaging solutions with personalized support and expert assistance.

FAQs

1. Why are flat pouches suitable for small brands?

Flat pouches are cost-effective, customizable, and lightweight, making them ideal for small brands with limited budgets and storage space.

2. Can flat pouches be customized for branding?

Yes, custom flat pouches for small brands allow full customization in size, design, and finish to match brand identity.

3. Are flat pouches durable enough for shipping?

Flat pouches offer strong barrier protection and durability, making them suitable for shipping and long-term storage.

4. Do flat pouches support sustainable packaging goals?

Many flat pouch options use eco-friendly materials, supporting sustainability and reducing environmental impact.